Pulp and Paper

Basics of Papermaking

This module describes the papermaking process from the paper machine approach system to the winder. It examines each section of the process and the various components that make up each section. While each paper machine is different, a typical machine might include an approach system; forming, press, and dryer sections; a coater, calender, reel, and winder; and a vacuum system.

Basics of Coatings and Coaters

This module describes the reasons for coating paper, and basic concepts related to coating and coaters. It examines the types of coatings used for paper products and how base sheet quality affects coating quality. The module then discusses coating ingredients and their production with respect to their place in the coating flow path. Next, it examines coating components that comprise the coating flow path including the mixer, storage tank, filters, and day tank. The module ends by discussing several types of coaters including blade coaters, roll/film coaters (rod metering size presses), and calenders.

Basics of Refining

This module discusses several aspects of refining pulp stock. It begins by discussing paper structure and fiber structure. Next, it covers the mechanics of refining, effects of refining, several types of refiners, and refining variables. The module concludes with a discussion of the impact of refining on the base sheet of paper.

Bleaching Chemistry

This module explains the theory and chemistry of various pulp stock bleaching methods. This is a generic module, but can be customized to deal with the bleaching processes used in any mill.

Brown Stock Washing

This module covers the principles and theory of washing pulp. This generic module provides some theory and background information related to the washing of stock to remove black liquor from pulp.

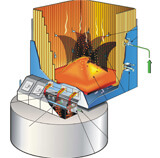

Digester Cooking

This module discusses the cooking of chips with white liquor. It discusses generic methods of cooking, with specific attention paid to continuous cooking. It explains ideal chip and pulp specifications. It also discusses effective cooking of chips to enable operators to understand the complete cooking process at a pulp mill.

Evaporators

This module is a brief overview of the evaporator process including the purpose and function of multiple effect evaporators. It explains key operating parameters that are critical to the evaporator process and operation.

Forming

This module begins with a basic discussion of flocculation. The remainder of the module discusses the headbox and the fourdrinier and how they contribute to the formation process on the machine. Forming is one of the most critical processes in producing a quality sheet that meets customer specifications.

Recausticization

This module shows and explains the Kraft process liquor cycle for green, white, and black liquor. It explains the chemistry of the recaust area, the lime kiln, and causticizing in operator terms.

Screening & Cleaning

This module introduces and explains the theory and practical applications of screening and cleaning of pulp stock. It shows and explains common types of screens and cleaners, and discusses operational considerations.

Wet End Chemistry

This module outlines the fundamental chemical additives used to produce a sheet of paper that meets customer specifications. It covers the basic chemical interactions that generally occur prior to the sheet being formed and dried on the paper machine. These interactions are caused by the addition of certain chemical compounds, or additives, to the process to achieve the desired properties required of the particular grade of paper that is being produced. The module provides a general description of each of the main additives, basic safety and handling procedures as well as specific reasons for the use of each.