Instrumentation & Controls

Controls & Logic 1

This module describes the ways in which process variables are measured and the engineering units used for measurement. It discusses measurement of level, pressure, temperature and flow in detail, as well as consistency and density.

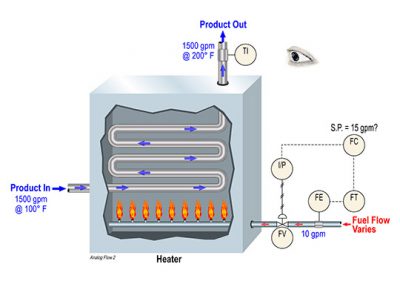

Controls & Logic 2

This module describes process control featuring analog and logic loops. Elements of control loops explained include sensors, transmitters, controllers, and actuators and their functions in manual and automatic modes, 3-15psig and 4-20mA signals, as well as ratio, cascade, and split range control loops. The module also discusses basic logic symbols (OR, AND, NOT).

Controls & Logic 3

This module explains PLC and DCS controls, using a typical DCS control system as an example. It also discusses PLC control theory with examples for simple uses. It discusses DCS control and explains system configuration and the different types of screen displays.

Direct Level Measurement Devices

This module covers the principles of direct level measurement including different types of direct level measurement devices such as floats, sight glasses, notched sticks, and gauge tapes.

Flow Measurement Devices

Available in e-Learning – Our Flow Measurement Devices module describes various types of flowmeters and their installations. The devices discussed include inferential flowmeters, mass flowmeters, and velocity flowmeters. The module also discusses how to use differential pressure to measure flow.

Indirect Level Measurement Devices

Available in e-Learning – Our Indirect Level Measurement Devices module covers the principles of indirect level measurement. It discusses how buoyant force, pressure, electric probes, and sound are used to measure level. It also describes devices within each of these categories, as well as devices that measure level indirectly using other methods.

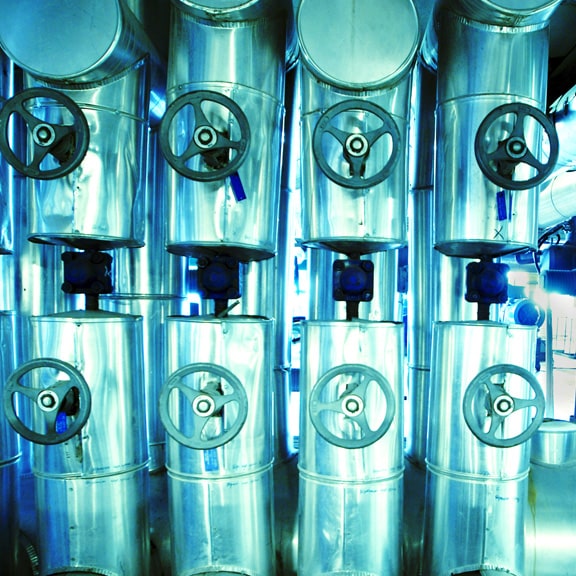

Pneumatics

This module introduces pneumatic applications, components, and systems. It takes a look at pipe, fittings, and hoses used in pneumatic systems. It discusses pneumatic components including various types of valves, motors, and turbines. The module also presents a simple pneumatic circuit and a pneumatic safety circuit to illustrate the theory and operation of pneumatic equipment.

Pressure Gauge And Transmitter Assemblies

Available in e-Learning – In this module we discuss pressure gauge and transmitter assemblies and how they work in liquid, gas, and steam service. The module also describes applications such as capillary seal systems and two pressure transmitters.

Pressure Measurement Devices

Available in e-Learning – Our Pressure Measurement Devices module describes various methods and devices used to measure pressure. It discusses the function of different types of electronic pressure transducers.

Principles Of Flow Measurement

Available in e-Learning – Our Principles of Flow Measurement module describes what flow is and how it is measured. It describes concepts related to flow measurement, including mass and volumetric flow rates, viscosity, velocity, and velocity profiles. The module also discusses flow measurement units for both mass and volumetric flow.

Principles Of Level Measurement

Available in e-Learning – Our Principles of Level Measurement module defines level, and discusses how to measure the level of liquids and solids. It gives an overview of direct and indirect level measurement. It also discusses single point and continuous devices.

Principles Of Pressure Measurement

Available in e-Learning – Our Principles of Pressure Measurement module describes what pressure is, what vacuum is, and different types of pressure. It discusses units of pressure measurement and the relationships between pressure and other process variables.

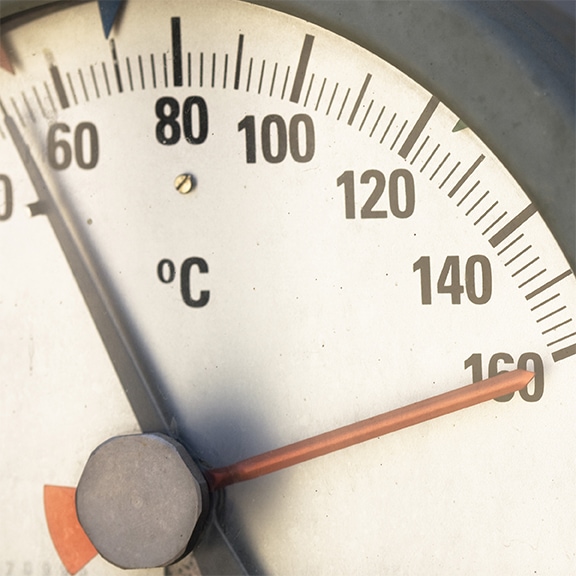

Principles Of Temperature Measurement

Available in e-Learning – Our Principles of Temperature Measurement module discusses the definition of heat and temperature, and different temperature scales. It reviews methods of temperature measurement including thermal expansion, thermal radiation, electromotive force, and electrical resistance.

Process Control Basics

This module provides an introduction to the subject of controls and logic. It is essential that the learner understands how process variables are measured. This module introduces the fundamental concepts of measurement and the methods of measuring process variables.

Reading P&IDs

This module explains the layout of P&IDs and shows drawing legend symbols, along with an explanation of each symbol, including mechanical, electrical, and instrument symbols. This module normally includes field exercises.

Reading P&IDs I: An Introduction

Available in e-Learning – This introduction module covers what a P&ID is and familiarizes the learner with the title block, and other important sources of information which are essential to understanding how to read a P&ID.

Reading P&IDs II: Equipment

Available in e-Learning – The second module in the four part Reading P&IDs course focuses on equipment and explains the symbols, identification tags, and labels used to identify key characteristics of industrial equipment.

Reading P&IDs III: Piping and Valves

Available in e-Learning – The third module in this four part course is devoted to piping and valves and explains the symbols and identification tags used to identify key characteristics related to piping, valves, fittings, and specialty items used in process systems.

Reading P&IDs IV: Instrumentation

Available in e-Learning – Module four of the four part Reading P&IDs course provides insight and understanding of the symbols and identification tags used to identify key characteristics of the instrumentation and control devices used in a process system.

Temperature Measurement Devices

Available in e-Learning – Our Temperature Measurement Devices module covers the concepts of thermal expansion, thermal radiation, electromotive force, and electrical resistance. It describes devices within each of these categories, including types of thermometers, thermocouples, and thermistors.